In the world of automotive diagnostics and repairs, the Engine Control Module (ECM) plays a pivotal role. Often referred to as the brain of the vehicle, the ECM is responsible for managing various engine functions such as fuel injection, ignition timing, and emission controls. However, like any electronic component, the ECM is susceptible to wear and tear over time, leading to malfunctions and performance issues in the vehicle. In such cases, an ECM rebuild becomes necessary to restore the functionality of the module and ensure the proper operation of the vehicle.

Understanding ECM Malfunctions

Before delving into the process of ECM rebuild, it’s crucial to understand the common malfunctions that can occur with this vital component. ECM issues can manifest in various ways, including:

- Faulty Sensors: Sensors that provide crucial data to the ECM can malfunction, leading to inaccurate readings and improper engine management.

- Corrosion and Moisture Damage: Exposure to moisture and corrosion can damage the internal circuitry of the ECM, causing it to malfunction.

- Software Corruption: Over time, the software programmed into the ECM can become corrupted, leading to erratic behavior and performance issues.

- Physical Damage: Accidents or mishandling can result in physical damage to the ECM, impairing its functionality.

The ECM Rebuild Process

ECM rebuild is a complex process that requires specialized knowledge and equipment. Here’s an overview of the typical steps involved:

- Diagnosis: The first step in ECM rebuild is diagnosing the root cause of the malfunction. This involves using diagnostic tools to scan for error codes and conduct comprehensive testing to identify the specific issues with the ECM.

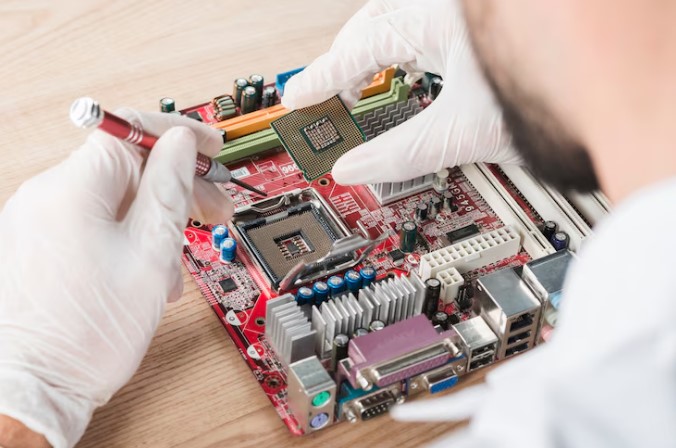

- Component Replacement: Once the problematic components within the ECM are identified, they need to be replaced. This may include faulty sensors, damaged capacitors, or other electronic components.

- Reprogramming: In some cases, reprogramming the ECM with updated software may be necessary to address software corruption or compatibility issues. This ensures that the ECM operates optimally with the vehicle’s engine and systems.

- Testing: After the rebuild process is complete, thorough testing is conducted to verify the functionality of the ECM. This includes testing for proper communication with vehicle systems, accurate sensor readings, and overall performance.

- Quality Assurance: Before the rebuilt ECM is returned to the vehicle, it undergoes rigorous quality assurance checks to ensure reliability and durability. This helps prevent future malfunctions and ensures customer satisfaction.

ECM Repair Solutions

ECM repair solutions encompass a range of services aimed at addressing ECM malfunctions and restoring the functionality of the module. These solutions may include:

- Component Replacement: Repairing or replacing faulty components within the ECM, such as sensors, capacitors, or connectors.

- Reprogramming: Updating the ECM software to address software corruption or compatibility issues and ensure optimal performance.

- Diagnostic Services: Comprehensive diagnostic services to identify ECM issues and develop tailored repair solutions.

- Quality Rebuilds: Professional ECM rebuild services that follow industry best practices to restore the ECM to like-new condition.

- Technical Support: Ongoing technical support and assistance to help vehicle owners troubleshoot ECM-related issues and ensure proper operation.

Conclusion

ECM rebuild is a critical aspect of automotive repair that addresses malfunctions in the engine control module. By understanding the process and utilizing ECM repair solutions, vehicle owners can ensure the reliable performance of their vehicles for years to come.