In the dynamic and demanding field of oil and gas exploration, one piece of equipment stands out as an unsung hero: the mud pump . Essential for the drilling process, mud pumps play a pivotal role in the effective management of drilling fluids, or mud, which serve multiple functions during the drilling of oil and gas wells. This article delves into the intricacies of mud pumps, exploring their functions, types, components, and advancements in technology.

The Role of Mud Pumps in Drilling Operations

Mud pumps are primarily responsible for circulating drilling mud down to the drill bit and back up to the surface. This circulation is vital for several reasons:

Cooling the Drill Bit: As drilling progresses, friction generates heat, which can damage the drill bit. Mud pumps circulate fluid to absorb and dissipate this heat, ensuring that the drill bit operates within optimal temperature ranges.

Carrying Cuttings to the Surface: Drilling generates rock cuttings, which must be removed from the wellbore to maintain drilling efficiency. The mud, pumped by the mud pump, carries these cuttings to the surface for removal.

Maintaining Wellbore Stability: The hydrostatic pressure exerted by drilling mud helps to stabilize the wellbore, preventing collapses and ensuring that the drilling process remains controlled.

Controlling Pressure: Mud pumps help to manage formation pressures, reducing the risk of blowouts—uncontrolled releases of oil, gas, or other formation fluids that can lead to catastrophic consequences.

Given these essential functions, the performance and reliability of mud pumps are critical to the success and safety of drilling operations.

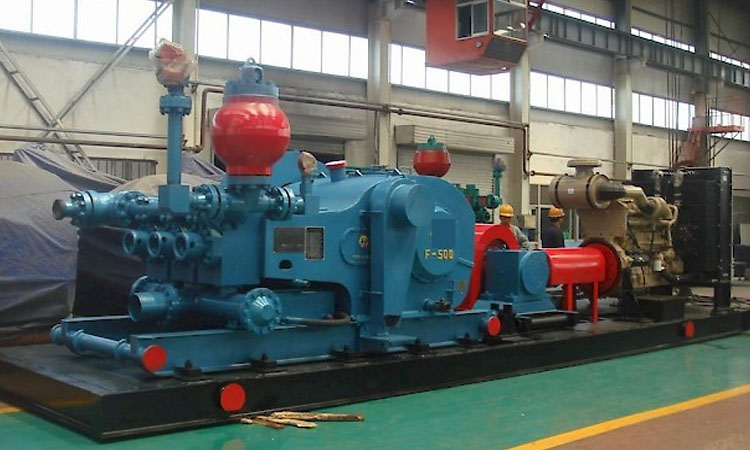

Types of Mud Pumps

Mud pumps come in several types, each tailored to specific operational needs and conditions. The most common categories include:

1. Positive Displacement Pumps

Positive displacement (PD) pumps are the most prevalent type used in drilling operations. These pumps work by trapping a fixed amount of fluid and forcing it through the discharge line. They excel in handling the high viscosity of drilling mud and maintaining consistent flow rates.

Subtypes of Positive Displacement Pumps:

Triplex Pumps: Featuring three pistons, triplex pumps provide a steady and efficient flow of mud. They are commonly used in drilling operations for their reliability and balance of performance.

Quadraplex Pumps: With four pistons, quadraplex pumps can achieve higher flow rates and pressure outputs than their triplex counterparts. They are typically used in heavy-duty applications requiring robust performance.

2. Centrifugal Pumps

While less common in traditional drilling applications, centrifugal pumps are utilized in certain scenarios where the fluid is less viscous. These pumps operate by using a rotating impeller to create flow. Their ability to handle fluid with lower viscosity makes them suitable for specific applications, such as mud mixing.

Key Components of Mud Pumps

Understanding the components of mud pumps is essential for appreciating their operation. The main parts include:

1. Pump Housing

The pump housing is the primary structure of the mud pump, designed to contain the internal components. It is built from robust materials to withstand the pressures generated during operation.

2. Piston/Cylinder Assembly

The piston/cylinder assembly is crucial for the pumping action. In positive displacement pumps, the pistons move back and forth within the cylinder, creating suction and pressure to draw in and push out the mud.

3. Suction and Discharge Valves

Suction and discharge valves regulate the flow of mud into and out of the pump. These valves open and close at the appropriate times to maintain pressure and prevent backflow, ensuring continuous circulation.

4. Drive Mechanism

The drive mechanism powers the pump, typically consisting of an electric motor or diesel engine connected to the pump through a series of gears or belts. This mechanism provides the necessary power to operate the pump efficiently.

5. Fluid End

The fluid end is where the mud enters and exits the pump. It houses the suction and discharge valves and components that interface directly with the drilling fluid.

6. Mud Hopper

The mud hopper is an auxiliary component that mixes drilling mud components before they enter the pump, ensuring the proper consistency and viscosity for effective pumping.

The Importance of Mud Pumps in Drilling

Mud pumps play a vital role in drilling operations, contributing to safety, efficiency, and environmental protection.

1. Safety

Safety is paramount in drilling operations, and mud pumps are critical for controlling wellbore pressure. By circulating drilling mud, they help prevent blowouts, which can result in devastating accidents and environmental disasters.

2. Efficiency

The efficiency of a drilling operation is closely tied to the performance of the mud pump. By maintaining a steady flow of mud, these pumps facilitate the removal of cuttings and help keep the drill bit cool, reducing downtime and enhancing productivity.

3. Cost-Effectiveness

Reliable mud pumps can lead to significant cost savings by minimizing non-productive time (NPT) and reducing the risk of blowouts. Efficient circulation of drilling mud helps ensure smooth operations, leading to faster drilling and lower operational costs.

4. Environmental Protection

By controlling wellbore pressure and reducing the likelihood of blowouts, mud pumps contribute to environmental protection. A blowout can lead to significant ecological damage and pollution, so effective mud pumps are essential for safeguarding the environment.

Advances in Mud Pump Technology

The oil and gas industry continuously seeks innovations to improve the performance and efficiency of mud pumps. Recent advancements include:

1. Automation

The integration of automation technologies in mud pumps has transformed their operation. Automated systems can monitor real-time data related to flow rates and pressures, allowing operators to make timely adjustments for optimal performance.

2. Remote Monitoring

With the rise of Industry 4.0, remote monitoring and control systems have become increasingly common. Operators can now oversee mud pump performance and adjust settings from onshore locations, enhancing flexibility and responsiveness in drilling operations.

3. Enhanced Materials

The use of advanced materials in mud pump construction has improved durability and longevity. High-strength alloys and composites are being utilized to withstand the harsh conditions of drilling operations, reducing wear and tear on components.

4. Energy Efficiency

Modern mud pumps are designed with energy efficiency in mind. Innovations in hydraulic design and the use of energy-efficient motors can reduce power consumption, leading to cost savings and a smaller environmental footprint.

Best Practices for Mud Pump Maintenance

Proper maintenance of mud pumps is essential for ensuring reliability and performance. Here are some best practices:

1. Regular Inspections

Conduct routine inspections to identify potential issues early. Check for leaks, monitor fluid levels, and examine the condition of pump components to prevent breakdowns.

2. Fluid Quality Monitoring

Regularly monitor the quality of the drilling mud, including viscosity, density, and composition. Maintaining the correct mud properties is crucial for efficient pump operation.

3. Lubrication

Proper lubrication of moving parts is vital to prevent wear and extend the life of the pump. Follow manufacturer specifications for lubrication intervals and types.

4. Component Replacement

Promptly replace worn or damaged components to prevent further damage to the pump. Keeping an inventory of critical spare parts can minimize downtime in case of component failure.

5. Operator Training

Ensure that personnel are well-trained in the operation and maintenance of mud pumps. Well-informed operators can identify potential issues quickly and perform maintenance tasks effectively.

Conclusion

Mud pumps are a cornerstone of mud pump operations in the oil and gas industry, playing a crucial role in ensuring safe and efficient drilling. By circulating drilling fluids, controlling pressure, and preventing blowouts, these powerful machines help maintain the integrity of the drilling process.

As technology continues to evolve, mud pumps are becoming more sophisticated, incorporating automation, remote monitoring, and advanced materials. Proper maintenance and adherence to best practices are essential for maximizing the performance and reliability of mud pumps.

In the quest for energy resources, the importance of mud pumps cannot be overstated. Their role in ensuring safe and efficient drilling operations highlights the necessity of these machines in the modern oil and gas industry.